THE REBUILD PROCESS

- We strip

- We clean meticulously

- We repair (if necessary)

- We assemble with new bearings

- We balance

- We test

These are the internal components of a Colombo RS110.22 ISO30 Toolchanging spindle.

All spacers and bearing journals are checked for wear and skimmed where necessary.

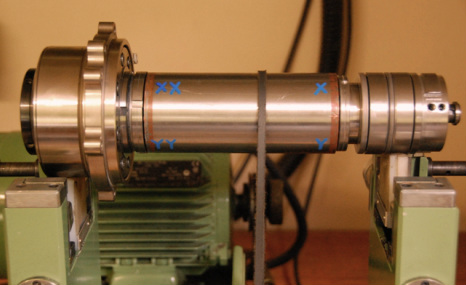

Prior to fitting Ceramic pre-greased bearings as standard, it is imperative that the shaft with all the moving parts is balanced.

All spacers and bearing journals are checked for wear and skimmed where necessary.

Prior to fitting Ceramic pre-greased bearings as standard, it is imperative that the shaft with all the moving parts is balanced.

The spindle cartridge is then dynamically balanced using a strobodyne balancer to a balance quality grade of G.04 This is the highest state of balance for any precision machinery.

Here are the internal components

of a HSD ES929 long nose shaft kit

Ready to rebuild

Finally the spindle after assembly is tested for:

Inputs from

a, Spindle stop sensor

b, Tool clamped sensor

c, cylinder withdrawl and eject sensors

Fan operation and condition

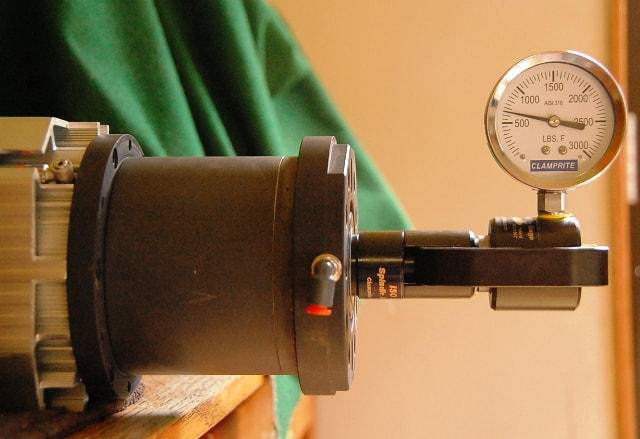

Cylinder operation and correct tool clamping pressure

All windings, rotor and stator checks.

The spindle is then run until the temperature reaches a normal level, this is important as the grease can generate a massive amount of heat until it is dispersed.

It is critical that the temperature is monitored during this running in phase.

Prior to despatch each rebuilt spindle is marked with our own unique number so we can trace the history should the spindle ever come back to us.

Inputs from

a, Spindle stop sensor

b, Tool clamped sensor

c, cylinder withdrawl and eject sensors

Fan operation and condition

Cylinder operation and correct tool clamping pressure

All windings, rotor and stator checks.

The spindle is then run until the temperature reaches a normal level, this is important as the grease can generate a massive amount of heat until it is dispersed.

It is critical that the temperature is monitored during this running in phase.

Prior to despatch each rebuilt spindle is marked with our own unique number so we can trace the history should the spindle ever come back to us.

Here is a broken balancing ring from a HSD ES919 9kW ISO30 Spindle cartridge. Normally the spindle would be scrap.

Next to it is a specialist repair we did to have a split balancing ring made.

Next to it is a specialist repair we did to have a split balancing ring made.

Here is the new balancing ring mounted to the spindle with a successful repair, the spindle was fitted with 4 ceramic bearings, balanced and tested.